- PRODUCT SPECIFICATIONS

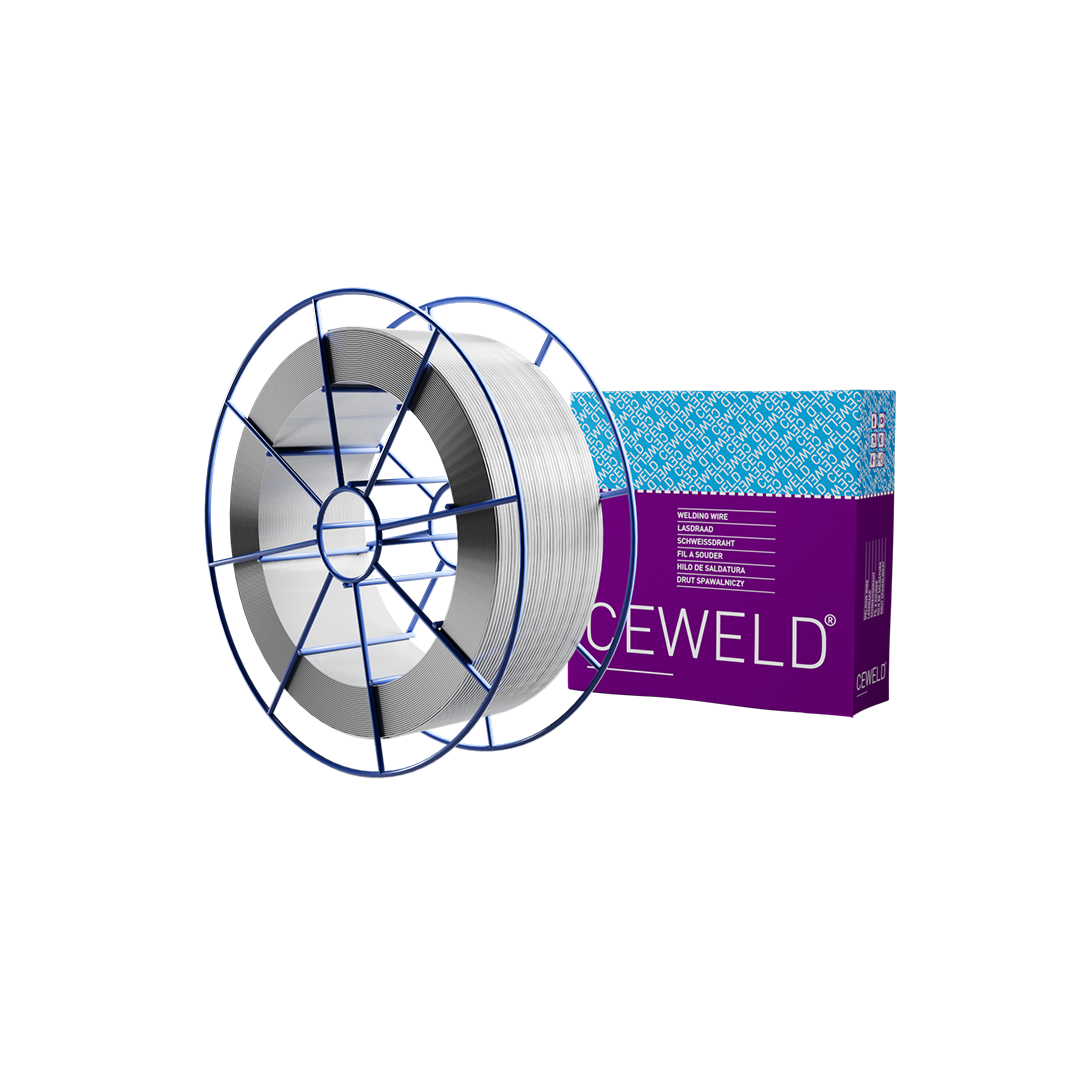

- PACKAGING

- Ask quotation

CEWELD® 410NiMo is used for welding similar martensitic and martensitic-ferritic steels in various applications such as water turbines, compressor construction, steam power plant construction, continuous casting rolls, centrifuges, valves, Pelton and Francis turbines.

CEWELD® 410NiMo is used for welding similar martensitic and martensitic-ferritic steels in various applications such as water turbines, compressor construction, steam power plant construction, continuous casting rolls, centrifuges, valves, Pelton and Francis turbines.

CEWELD 410NiMo has comparable properties to steels of the same or similar types. It is resistant to water and steam.

The preheating and interpass temperature should be 100 - 160°C for thick-walled parts.

The heat input should be max. 15 kJ/cm. Annealing at 580 - 620°C is possible.

13%Cr - 4%Ni - 0,5%Mo Steel

1.4000, 1.4001, 1.4002, 1.4313, 1.4317, 1.4407, 1.4413, 1.4414,

GX4CrNi13-4, X3CrNiMo13-4, GX5CrNiMo13-4, GX4CrNiMo13-4, X 6 Cr 13, X 7 Cr 14, X 6 CrAl 13

ACI Gr. CA 6 NM

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Impact Energy (J) ISO-V | Hardness | |

|---|---|---|---|---|---|---|

| RT | -20°C | |||||

| As Welded | 650 | 790 | 15 | 50 | 38 HRc | |

| 580°C±15°C 8h | 765 | 840 | 18 | 50 | 40 | 250 HB |