- PRODUCT SPECIFICATIONS

- PACKAGING

- Ask quotation

Ti Stabilized ferritic stainless steels, Austenitic stainless steels and in both homogeneous and heterogeneous sheet metal configurations (sheets of different grades welded together). CEWELD 430 Ti is an excellent choice to weld automotive exhausts as well as flues and ducts subject to moderately high temperatures. CEWELD 430 Ti can be used to weld aluminized 409 and 439 provided sufficient filler metal is added.

Ti Stabilized ferritic stainless steels, Austenitic stainless steels and in both homogeneous and heterogeneous sheet metal configurations (sheets of different grades welded together). CEWELD 430 Ti is an excellent choice to weld automotive exhausts as well as flues and ducts subject to moderately high temperatures. CEWELD 430 Ti can be used to weld aluminized 409 and 439 provided sufficient filler metal is added.

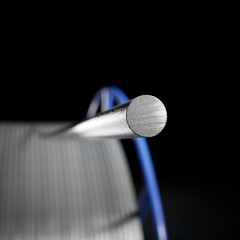

CEWELD 430 Ti is a 18%Cr alloy stabilized with Ti. This alloy has improved oxidation and corrosion resistance over an ER409 alloy. Single pass welds on light gage base metal or welds with preheat do not usually require PWHT.

1.4000, 1.4002, 1.4016, 1.4057, 1.4113, 1.4740, 1.4742, 1.4057, 1.4059, 1.4741, 1.4509, 1.4510, 1.4511, 1.4512, 1.4520, 1.4523, 1.4712, 1.4713, 1.4724,

X7Cr14, X12Cr13, X17CrNi16-2, X6Cr13, X6CrAl13, X6Cr17, X 6 Cr Mo 17, X17CrNi16-2, X2CrTiNb18, X3CrTi17, X3CrNb17, X2CrTi12, X2CrTi17, X10CrSi6, X10CrAlSi7, X10CrAlSi13, X10CrAlSi18

UNS S40300, S40500, S40900, S41000, S42900, S43000, S43035, S43036, S43100, S44200

AISI 403, 405, 409, 410, 429, 430, 430Cb, 430Ti, 439, 431, 442

| Heat Treatment |

RP0,2 (MPa) |

Rm (MPa) |

A5 (%) |

Hardness |

|---|---|---|---|---|

| As Welded | 320 | 480 | 17 | HRc |